Dancop Shares Findings on Thermal Paste and Skylake: Thermal Grizzly Kryonaut Top Pick for Extreme Overclocking

The Dancop "ICE-Ball" effect on Skylake CPUs is the audible crack when the contact between the CPU die and IHS, and IHS and CPU pot, is lost. The loss of contact is significant for the overclocking capabilities of your processor as the thermal conductivity is reduced to the minimum. Overclockers have been struggling with the "thermal paste crack" problem for a long time, and Skylake doesn't make things easier.

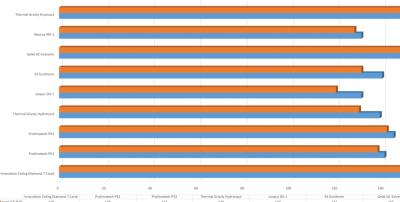

As Skylake requires delidding to achieve the highest frequencies on liquid nitrogen, there are now two problem points for thermal paste (CPU-IHS and IHS-cooler). In a forum thread posted in the Skylake OC sub-forum, German overclocker and current #1 in the world, Dancop shares his findings on the ICE-Ball effect using different thermal pastes. Among the thermal pastes tested are: Innovation Cooling Diamand 7 Carat, Prolimatech PK1 and PK3, Thermal Grizzly Hydronaut and Kryonaut, Junpus DX-1, EK Ecotherm, Gelid GC-Extreme, and Noctua NH-1.

The results are spectacular. The ICE-Ball temperature under load varies between -120°C (Junpus DX-1) to -185 (Thermal Grizzly Kryonaut). That's 65°C difference for minimum load operating temperature! Check the thread for more information and detailed graph!

Hey GUYS!

I did a lot of testings the last weeks...

Spent more than 150L of LN2, hopefully to help you guys, not doing the wrong TIM on your Skylake DIE

My testsystem is:

What have I done?

I put all the following TIMs on the DIE of the CPU. On the Intel HS I always used Thermal Grizzly Kryonaut!

TIMs I've used:

Then I went into Windows 7 64bit with the following settings:

5200/5200 on the core/cahce

Voltages:

Temperature measured with the ASUS Batmobile (OC-Panel 2)

For each TIM I've tested it twice with de-mounting and renewing all the TIM!

Then I did two several tests. Finding the "Crack-Point" in idle and on load (Cinebench R15)!

The "Crack-Point", I call it Ice-Ball point, cause it sounds (it is truly hearable!!!) like the little Ice-Ball which you have to crack in Taiwanese menthol cigarettes, when the TIM reaches its lowest temperature, before it looses contact to the POT, IHS or DIE. For me it looks like it's a matter of bonding agent (I don't know the right expression in english! I mean the fluid, that makes the TIM more or less fluent). When this "bonding agent" gets too cold, then it starts to get hard and cracks because of the different coefficients of expansion between silicium and copper.

You can reproduce cracks when you are on heavy load and the pot is very cold and your cpu crashes. Then the silicium turns from approximately minus 20 degrees to minus 160 within a milisecond!

The copper from the pot and the IHS already has its typical size for this kind of temperature, but the silicium changes it right now, which makes it much smaller compared to the size it has while load!

The most important thing is the follwing; mount your pot as tight as it goes! At least, that's what I found out!

Now you wanna know which TIM is the best (I can only name the pastes I've tested, so if one is missing, let me know, or if you're a TIM vendor....send me!)

Here ya go:

Please guys, share your experiences...I hope we can find THE right TIM soon!!!!

Right now it is Thermal Grizzly Kryonaut!

Great test. Thanks for sharing Daniel

We had the crack way earlier than -180. Depending on clock frequency/volts we could not even surpass -145°C before we lost it....

Ourt best temp region with Grizzly was between -125°C / -145°C max. If we lost contact best to torch till -40ish and then slowly build up the clocks/temp

That's what I meant with....as tight as it goes

With 5 rounds of the screw...136

with 10 165

with 17 ( more is not possible) 185

GC-extreme and Kryonaut are way above the others

Definetly a target product for overclockers it seems.

Thanks for sharing

Indeed!

OMG...3 people watching it within some minutes...seems to be interesting

Thank you soo much Daniel San

This is a huge help for guys like me !!

Also this i did not understand what you meant .. ??

Is this the temps you could bench at with the amount of rotations on the screws ?

Exactly. ..beast mounting only

Thank you soo much

One last question..

Did you use the springs or no need for them ?

Thank you sooooo much for all the help !!

Sure...that's what I'm talking about!

With the beast springs and the named rounds of the screws

Thank you very much for these tests

But what about heat transfer from DIE to HS?

I mean... Do we really care about the best Temps, or the best clocks. Did you test highest clocks on fixed VCore or sth like this?

Yes I did...Except for PK1, Hydronaut and NH-1

They were too bad!

max Clocks in R15

Kryonaut 6320

Diamant 6150

PK3 6100

DX1 6080

EK Ecotherm 6100

Gelid 6280

Great to see a round up like this since Thermal Grizzly was released some days ago

Would like to see more testing!

Regards

Great findings! Thank you for sharing!

Welcome

very nice effort i guess not a big surprise anymore Grizzly is the best TIM on the market!

-> 17 rounds without spring.... that's tight indeed

Thanks for sharing

I guess our Ectotherm does well, considering I validated it to -50°C

Good work Daniel!

How do you guys get the kryonaut to such low temps without cracking? Tried Z170 on LN2 for the first time today and got the crack at -145. This was with my Kingpin EE with supertight mount! Springs fully compressed. And they are quiet sturdy...

Do you use a thin or a little thicker layer?

depends how aggressively you pour. you have to go super slowly. if you want to go over crack point you must have 1 degree increments past the "noisy" point of the pot.

it also depends where you mount your probe and what equipment you use, maybe you are at -160 compared to other guys. So there are many factors. But for me to get no crack is very clean die and hs , then apply one line on the die, mount ihs, then one line on the ihs, mount pot with moderate settings, i dont like tight .

.

Excellent thread and work daniel, awesome!

Thx!

Exactly Vivi!

Pouring is everything! Beast is very fast, but that's exactly what the pastes don't like. Be patient...slow...not aggressive

says:

Sorry daniel....the original tim, cracks???

What was the max cb before delid???

Thanks bai

Around 120...

says:

Wow.....

Problem is, I only had original tim on my 6700k. My 6600k was delidded before I've done this test.

So I thought it wouldn't fit into this test...

says:

So, on your 6700k with the original tim, you had problem under -120°.....then you change tim...right???

Exactly

says:

Okkkkkk....so i have to change the tim on my cpu:(( fingercross uff

yes there is no way to test max clocks without delid

says:

The cpu can be closed forever, after change the compound??? Because i think after some cpu's remount, the die could be scratched.....

dont worry bro i have same issue... maybe we pour still too fast

nono you have to refresh TIM after/before every session to achieve top clocks all the time

Thanks for the replies guys!

Please log in or register to comment.